China's Game-Changing Fatigue-Free Alloy Sparks Aerospace Revolution

Chinese scientists have discovered a method to conquer metal fatigue through a process that converts regular stainless steel into a substance robust enough for aerospace And other premium applications, as stated in a study published in the peer-reviewed journal Science.

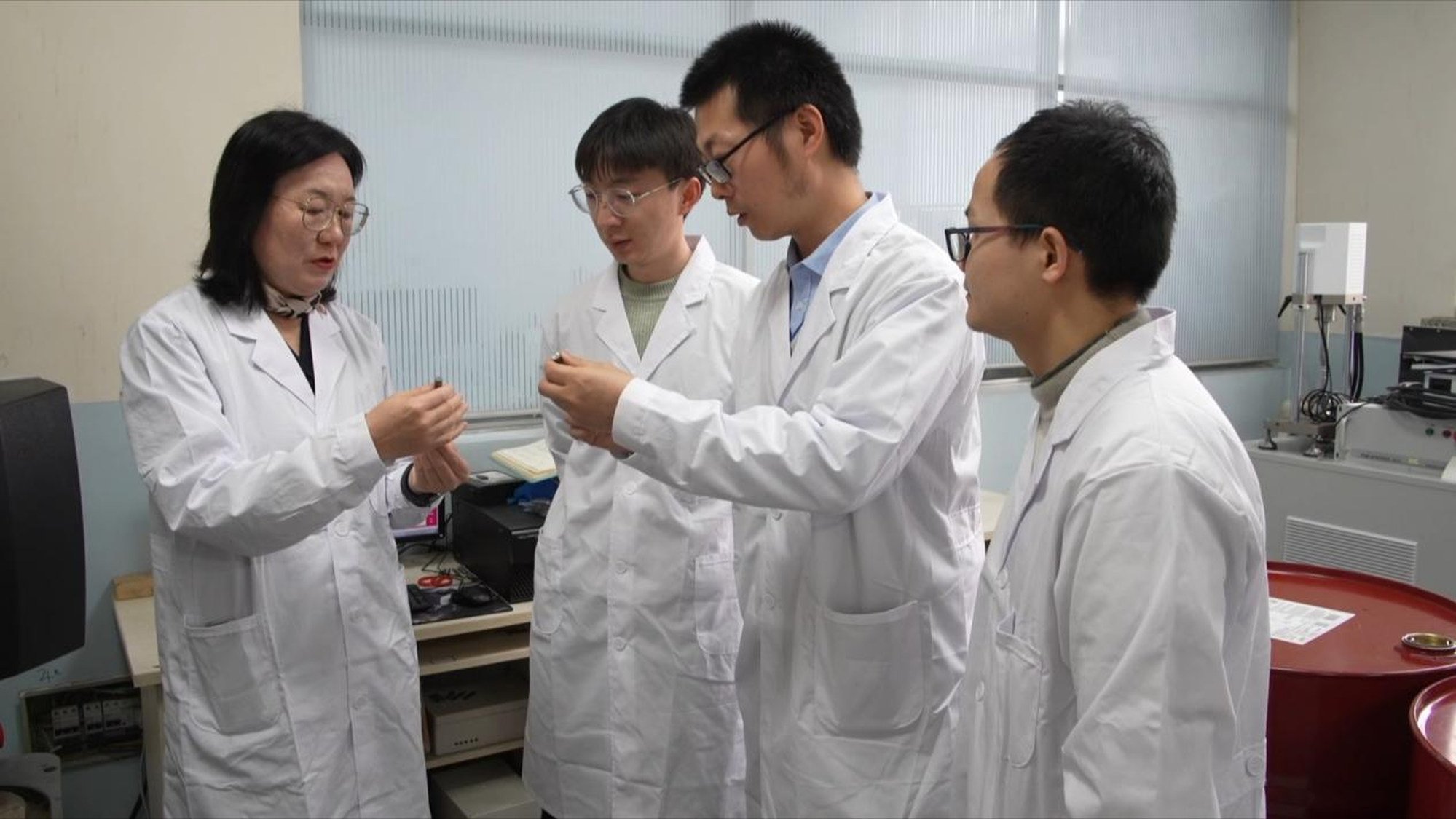

The research team from the Chinese Academy of Sciences' Institute of Metal Research managed to enhance the strength and durability of steel by modifying its internal structure through a process akin to wringing out a towel, according to the report.

Not only did the alteration boost the material’s yield strength significantly, but it also enhanced its resilience against cumulative damage from metal fatigue by as much as 10,000 times, according to the research released on April 4th.

Are you looking for insights into the most significant issues and developments globally? Find your answers here. SCMP Knowledge Our latest platform features handpicked content including explainers, FAQs, analyses, and infographics, all provided by our esteemed team of experts.

Possible uses might encompass submarine pipelines along with engine parts like crankshafts and connecting rods that endure high pressures. This advancement could additionally provide technical backing for sophisticated equipment manufacturing and various engineering fields.

During an interview with China Central Television, the research team lead, Professor Lu Lei, stated that there were no noticeable changes to the material’s exterior before and after treatment; however, he noted that “its internal structure has undergone transformation.”

She mentioned that despite having a diameter only one three-hundredth the size of a human hair, this skeletal structure has an important function under pressure.

Conventional metal alloys may break or splinter when exposed to abrupt external stresses that surpass their yield strength. However, these materials are likewise prone to fatigue when enduring continuous stress levels beneath this limit.

Eventually, this may result in permanent distortion due to accumulated stress, which can lead to tiny fissures, shape alterations, and—in extreme situations—sudden collapse without prior indication.

This effect, referred to as cyclic creep, generally happens when materials endure elevated temperatures or prolonged stress – examples include turbine blades, suspension bridge cables, and the boiler tubes within nuclear reactors.

Boosting the toughness of materials employed in high-stress conditions usually detracts from their ability to resist fatigue, posing a substantial hurdle for experts in materials engineering.

Researchers have extensively worked towards reducing the effects of creep by implementing various advancements such as enhancing materials, optimizing structures, and applying surface treatments.

By innovatively restructuring the metal’s crystalline arrangement, Lu and her colleagues have created a process that converts 304 austenitic stainless steel into an extremely robust form known as gradient dislocation structured (GDS) steel.

The alteration enhances the yield strength by 2.6 times and improves cyclic creep resistance by a factor of 100 to 10,000 when compared to other high-strength alloys, as stated in the research paper.

The research team generated a spatially graded, stable dislocation configuration within the metal by subjecting it to repeated torsional deformation using a specialized apparatus. This resulted in an intricate, sub-micrometer-sized, three-dimensional barrier within the material, which enhances resistance against possible harm from exterior stresses.

By using instrumentation for observations, the team discovered that these "walls" acted akin to springs, soaking up the force whenever an external pressure was exerted upon them.

When exposed to shocks, they initiated thicker, more refined anti-crash barriers, resulting in the metal becoming increasingly robust as the pressure increased. The team noted that these secondary responses were evenly distributed, thus avoiding localized distortions.

Lu's group specializes in nanostructured metal materials and has released multiple associated papers in Science starting from 2018.

This recent accomplishment not only shatters the theoretical "impossible triangle" in metallic substances—where enhanced strength, ductility, and stability were once considered incompatible—but also demonstrates significant promise for real-world uses.

The CCTV report pointed out that 304 stainless steel, which forms the foundation of GDS steel, is extensively utilized and comparatively affordable.

The distinctive design mainly stems from cyclical torsion, which involves an initial setup cost for machinery but doesn’t necessitate complicated processes involving extreme heat or pressure.

It suggests that this gradient dislocation structure, serving as a flexible approach for enhancing toughness, holds potential across multiple engineering alloys.

The report further noted that it is anticipated to offer essential backing for the extended service life and robust dependability of crucial elements operating in severe conditions, like those utilized in aviation.

More Articles from SCMP

China's CATL maintains confidence in Hong Kong with intentions to listing this quarter, according to sources.

A deepfake video featuring Hong Kong's John Lee promotes a fraudulent investment plan.

Mario Carbone’s fiancée, Cait Bailey, resembles Margot Robbie and is a prominent publicist known for representing figures such as Zayn Malik, TikTok stars Charli D'Amelio and Alix Earle, and podcast host Alex Cohen.

How Hong Kong Universities Are Molding the Arts' Future

The article initially appeared on the South China Morning Post (www.scmp.com), which is the premier source for news coverage of China and Asia.

Copyright © 2025. South China Morning Post Publishers Ltd. All rights reserved.